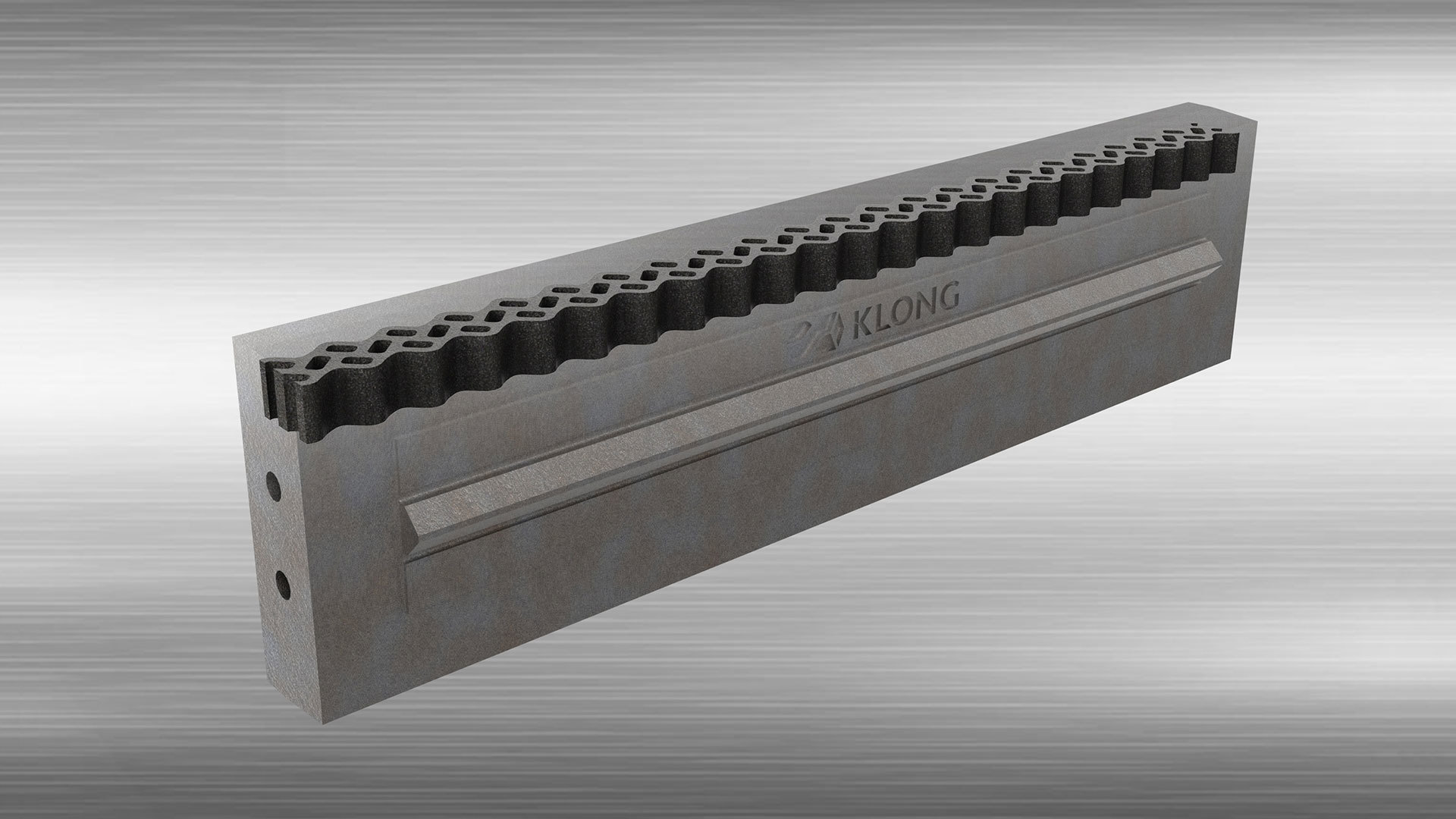

Impactor Wear Parts

High chromium or martensitic ceramic plate hammers are used in impact crushers to crush high abrasion materials such as limestone, granite, or construction waste. The embedding of ceramics can greatly increase the service life of the plate hammer, usually reaching 2-3 times the service life of ordinary high chromium or martensitic plate hammers.

MORE +Shredder Hammers

We Manufacture anvils & impellers for VSI (Vertical Shaft Impactor) crushers. These parts could be made in hi-chrome white irons or with ceramic inlaid. With ceramic inlaid on the most wearing areas,

MORE +Grinding Roller

We manufacture wear plates,liners and impact plates for crushers, mills and grinders. The wear plates and liners can be made with different materials or solutions to be fitted on equipment and applied

MORE +Wear-resistant Composite Plates

We manufacture liners used on ball millers according to specifications provided by customers. Moreover, we provide ceramic insert solutions for mill liners to extend the wear life of liners.

MORE +Other Parts

Wearsolutions: •Manganesesteel(+carbides) •Martensiticsteel(+ceramics) •Highchromecasting(+ceramics) Wearparts •Blowbars,impactplates,linersforimpactcrushers. •AnvilsandlinersforVSIcrushers. •Hammersf

MORE +Impactor Wear Parts

Shredder Hammers

Grinding Roller

Wear-resistant Composite Plates

Other Parts

Kinglon New Material

Yiyang Kinglon New Material Co., Ltd. is a provincial-level high-tech private enterprise integrating scientific research, production and trade. It was established in 2007 with a registered capital of 50 million yuan and is located in Meilin Industrial Park, Yiyang High-tech Development Zone. The company is mainly engaged in the research and development, production and sales of metal manganese alloy additives, iron-based ceramic composite wear-resistant materials and other products. The production base is 45 mu, the factory floor area is 11000 square meters, the R & D center is 1000 square meters, and the office and living facilities are complete. At present, the company has set up a municipal R & D center, with more than 10 sets of advanced product R & D and testing equipment, an automatic manganese alloy ball production line with an annual output of 60000 tons, a lost foam production line with an annual output of 3000 tons of composite wear-resistant materials and a water glass cavity production line with an annual output of 5000 tons of iron-based ceramic composite wear-resistant materials.

Learn more →Established Kinglong New Material

Kinglong New Material Registered Capital

production base

The annual output value of Kinglong New Materials reaches 0.2 billion yuan

News dynamics

Contact Us

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.