Purpose:

Jaw crusher is mainly used in metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics and other industrial sectors for crushing and fine crushing of various medium hard ores and rocks. Generally used to make head break, also called rough break, first break. Suitable for crushing all kinds of soft and hard ores with compressive strength not higher than 320MPa (mpa).

How it works:

The working principle of jaw crusher: When the motor rotates the eccentric shaft through the belt, the vertical connecting rod moves upward and downward, when the vertical connecting rod is upward, the two elbow plates are gradually flattened, the elbow plate forces the movable jaw plate to push the fixed jaw plate, the ore in the crushing chamber (that is, the space composed of the fixed jaw plate and the moving jaw) is crushed, split, and broken.

Structure and performance:

Advantages:

1, compact and simple. Easy to operate, more convenient maintenance, downtime and maintenance time is greatly shortened.

2. Stable performance. The jaw crusher can maintain the operation under high strength pressure, and the durability and reliability are extraordinary, which is a major support point of the jaw crusher.

3, gasket type discharge port adjustment device, reliable and convenient, large adjustment range, increase the flexibility of equipment.

4. The crushing ratio is large. The most prominent advantage of the jaw crusher is the extremely high crushing ratio, the crushing chamber is deep and there is no dead zone, which improves the feeding capacity and output, improves the crushing performance, and the product particle size is uniform.

Disadvantages:

Work intermittently, with idle travel, increasing unproductive power consumption. When the wet material is broken, the production capacity decreases and plugging occurs. When the dry sheet material is broken, the degree of crushing is not large, which is easy to cause blockage of the feed port of the discharge chute or the lower crusher.

Wearing parts:

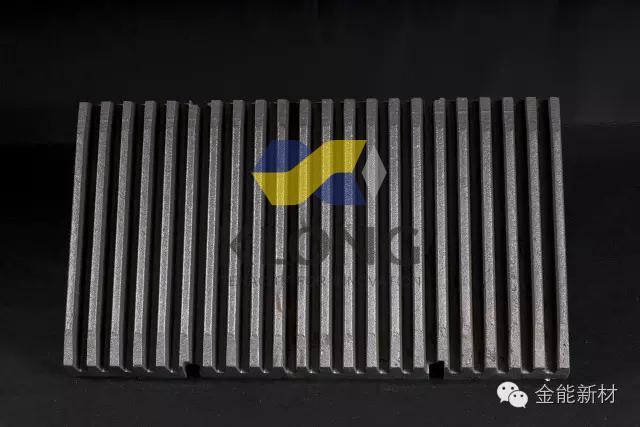

1, jaw plate - also known as tooth plate, tooth plate, used to break the material of the main wearing parts, its replacement cycle depending on the different crushing materials are different, is the highest frequency of replacement on the jaw crusher wearing parts. According to its function can be divided into two categories: movable board, fixed board. According to the installation method, it is divided into: horizontal installation and longitudinal installation.

Movable jaw plate (longitudinal mounting)

Fixed jaw plate (longitudinal mounting)

Movable jaw plate (lateral mounting)

Fixed jaw plate (lateral mounting)

2, the press block - used to hold the movable plate and the stationary plate

In Figure 2 and 3, respectively, are the fixed plate and the movable plate.

Block

3, elbow plate - also known as push plate, mainly to push the movable jaw plate to the fixed jaw plate

Bracket

The main wearing parts in the figure are “ Jinneng new Materials ” The production of high quality high manganese steel products, products are shot in kind.

The high manganese steel products produced by us have pure raw materials, excellent heat treatment process, and certain improvement in wear resistance compared with ordinary high manganese steel products on the market. Welcome to your attention “ Jinneng new Materials ” For more information, please call 0737-6181528.