Purpose:

Hammer crusher is used to break all kinds of medium hard and weak abrasive materials. The compressive strength of the material does not exceed 100MPa, and the moisture content is less than 15%. The materials to be crushed are coal, salt, gypsum, brick, silica, limestone, etc.

How it works:

The hammer crusher mainly relies on the impact of the crusher's hammer head to break the material, in the lower part of the rotor, the sieve plate, the material enters the crusher, and is immediately crushed by the impact of the high-speed rotating hammer head. The particle size of the crushed material is less than the size of the screen through the sieve plate discharge, and the larger particle size of the material, the granular material that springs back to the lining plate, will also be subject to the additional impact of the hammer crushing, in the whole process of the material crushing, the material also impact and crush each other. The broken material obtains kinetic energy from the hammer head and impacts at high speed to the lining plate on the inner wall of the casing and breaks for a second time. Finally through the sieve plate (sieve strip) discharged out of the machine.

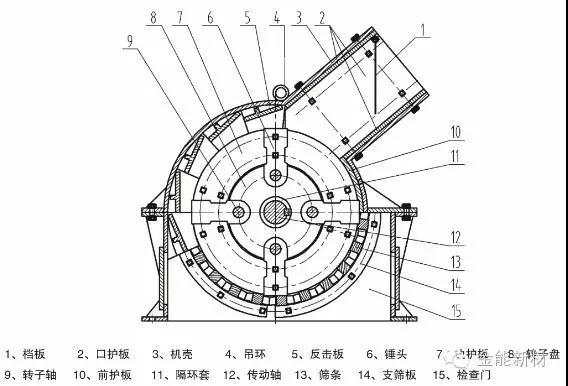

Structure and performance:

Advantages:

1, with large feeding particle size, fine crushing ratio, high efficiency;

2, simple structure, compact assembly, light weight;

3, uniform product particle size, less crushed powder;

4, easy installation, easy maintenance;

Disadvantages:

When the crushing hardness is high, the hammer loss is large, and the hammer replacement frequency is too high

Wearing parts:

1, hammer - also known as the crushing hammer, used to break the main wearing parts of the material, according to the material can be divided into the following categories:

A, high chromium alloy hammer (suitable for crushing occasions with little impact, generally suitable for use after jaw breakage)

Two, high manganese steel hammer (suitable for large impact, large materials used in harsh conditions, generally used to do the first break)

3, alloy steel hammer (suitable for the above two working conditions)

High Chrome hammer

High manganese steel hammer

Alloy steel hammer

2, lining plate - used to protect the crusher body and crushing materials, the lining plate produced by Jinnong has solved the problem that the alloy lining plate is easy to break and crack, has achieved the best balance between wear resistance and impact toughness, and can completely replace the traditional high manganese steel lining plate products in the hammer crusher, depending on the different materials, its life is 1.8 to 3 times that of high manganese steel lining plate.

3, screen strip (screen plate) - used to screen the broken fine material, because of its porous structure, mostly made of high manganese steel.

Sieve strip (sieve plate)

The main wearing parts in the figure are “ Jinneng new Materials ” The production of high quality products, products are shot in kind.

Welcome to “ Jinneng new Materials ” And share to the circle of friends, so that more customers know our quality products.